"How I Do It"

Window Crank and Door Handle Removal Tool

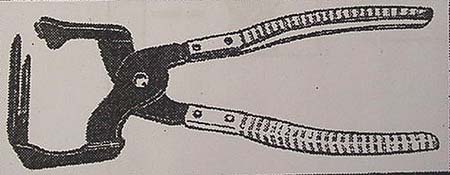

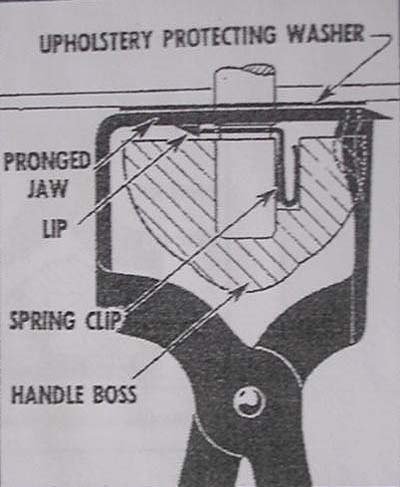

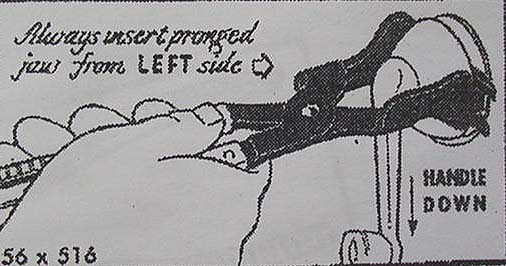

This is the tool illustrated in the factory service manual, and how it is supposed to be used.

Click here for more pictures of the KD tool.

Since they are difficult to find and expensive to buy for occasional hobbyist use, I made my own. I fabricated a gizmo to release the steel spring clip that holds the door handles and window cranks to the 3/8" square shafts on the window regulators and latch assemblies of our 1955 Chrysler C-300. I think this tool will work on a broad spectrum of MoPar door and window handles.

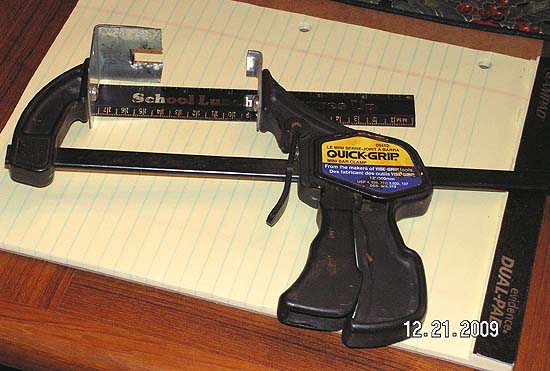

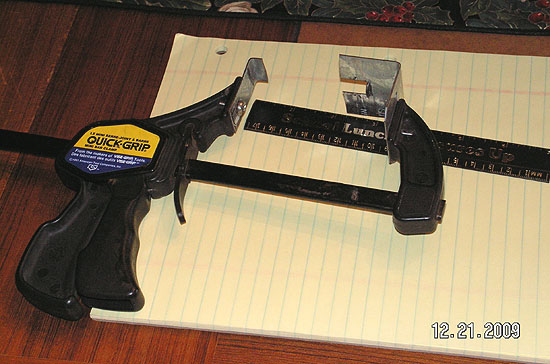

I used a 12" light duty Vise Grip/Quick Grip mini bar clamp having removable pliable pads that slip over the black plastic jaws. I see at Lowes they are now Irwin brand and they are only available in 2-packs. They are also available in 6" and that would work ok but might make the drilling and tapping tasks more difficult. Price is about $20 for two.

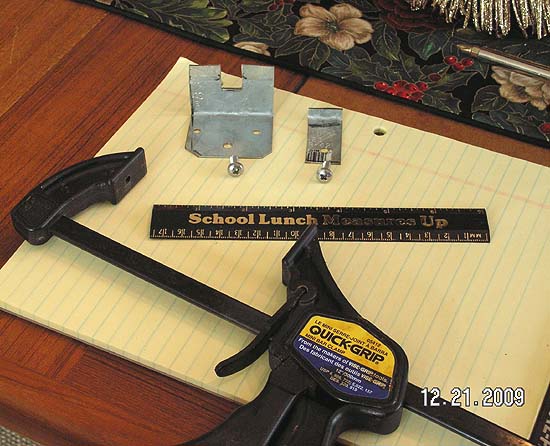

While at Lowe's, pick up one Simpson Strong Tie A34 Angle Brace ($0.78). There will be a large selection of these galvanized steel pieces used to fasten, support and reinforce wood framing. It is strong enough to do the job. I also picked up two machine screws, 10-32 x 1/2". If you don't have a tap for that thread, beg, borrow, or buy one. Also make sure you have 3/16" and 11/64" drill bits and a good, sharp hacksaw blade to cut up the brace as it is tough stuff.

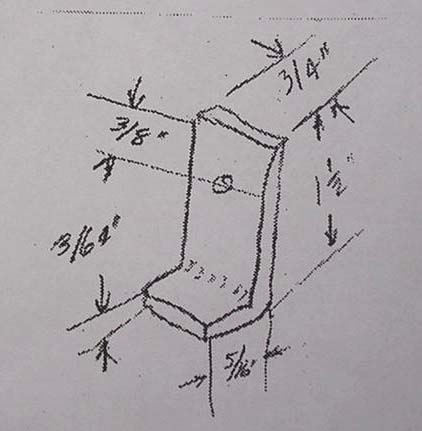

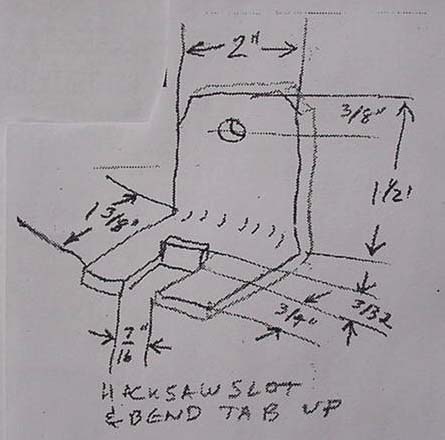

1. Cut a 3/4" strip from the right edge of the brace as shown. Call this piece "Smallfoot".

2. Trim Smallfoot to leave a 5/16" foot. Drill the existing hole out to 3/16". Smooth sawn edges with a file or grinder.

3. Now we make the other piece, "Bigfoot". Cut ½" from the longer leg.

4. Cut a 7/16" wide strip in the lower leg of Bigfoot-no wider! Grip the strip with a narrow pliers or an adjustable open-end wrench and bend the strip in a vise at 90 degrees to the base, hammer it to make a good right angle bend and cut it off leaving a 3/32" tab. This tab will engage the spring clip. Drill the existing high and centered hole out to 3/16". Smooth sawn edges with a file or grinder.

5. Remove the pliable pads from the jaws of the clamp.

6. Drill 11/64" holes in the centers of the plastic jaws. ¾" deep. Tap the holes with a 10-32 tap.

7. Attach Smallfoot to the moving jaw and Bigfoot to the stationary jaw of the clamp with 10-32 x ½" machine screws.

To remove a window crank:

1. Position the crank with the handle in the down position.

2. Open the jaws somewhat wider than the base of the crank. Slide Bigfoot under the left hand side of the crank, pressing in on the door panel to allow the 3/32" tab to slide under the edge of the base. It should engage and butt up against the spring clip. You might manually press Bigfoot in to release the spring clip here. Otherwise,…

3. Bring Smallfoot to and under the right edge of the crank base with the clamp grip. Continue to squeeze the grip to engage and slightly compress the spring clip. The clamp will hold the spring in the compressed position.

4. Grasp the bar of the grip and remove the crank. You may have to wiggle the clamp and crank a little if the crank is stuck to the regulator shaft. The shafts on my car had been oversprayed at some time and the paint acted like glue.

To remove a door handle:

Same as with the window crank, with the door handle pointing down and Bigfoot sliding in from the left.

To reinstall either the crank or door handle, clean the shaft using a wire brush if necessary. A little dab of WD-40 or light oil on the shaft might be appropriate here—but not so much as will run out onto the door panel. Make sure the notch for the spring clip is free of gunk. Make sure the window crank is at an optimum position when the window is up so that the driver's or passenger's knee is not bumped by the crank handle. Slide the handle or crank over the shaft and bump it into place with the palm of your hand or a rubber hammer. The spring clip should re-engage into the notch on the shaft. Give the handle a tug to make sure it is set.

There is no need to use the gizmo to reinstall the handle.

Remove Bigfoot and Smallfoot, put them where you can find them, reinstall the pliable pads on the clamp and continue to use if for its proper use.

Rich "Rube" Barber

Brentwood, CA

C300@ez2.net