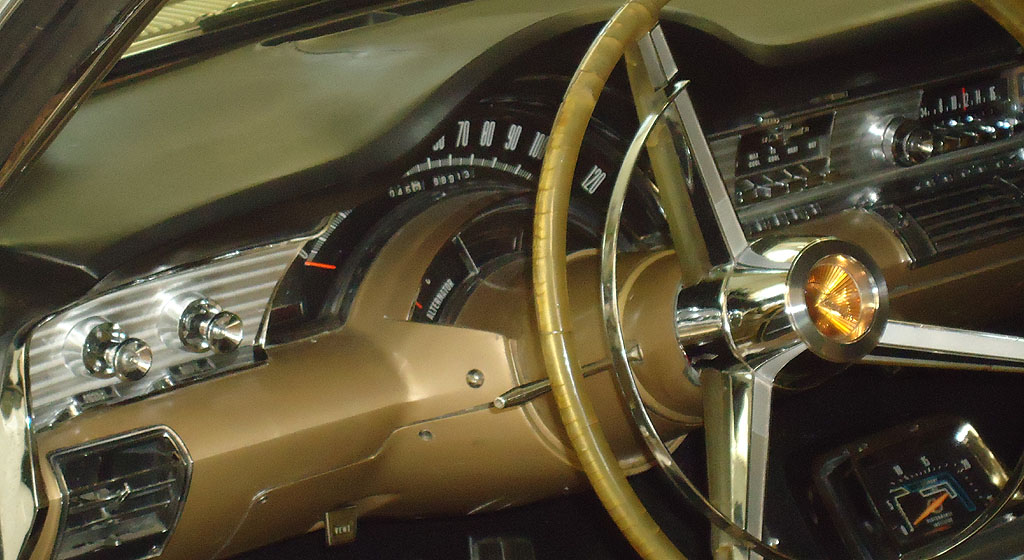

Installed a replica dash in a 300L

My

L is not a show car. It is becoming a reliable road car, and year

before last I drove it across N.H. (around Mt. Washington) and Vt.,

and ferried across Lake Champlain to make the Fall Meet at Lake

George. The car performed well, and got lots of looks. Messrs.

Merritt, Miklas and Verity went to dinner in it, and on the way we

examined and discussed the dashboard.

As

far as I knew, the dash in my L was as good as anybody else’s—but

I was soon corrected. My dash was plain aluminum, no pattern, no

shine, no nothin’. My riders all knew there was supposed to be

a pattern, and we thought it might be the same as the engine turning

design on the rear, above the bumper. And, one of them brought some

feet of an appliqué with a very similar engine turned pattern.

I put some on the right hand side by the glove compartment. It

looked some good!

When

I got back home to and

slathered the whole dash

An original dash looked like it had holographic lines on it, and careful

inspection showed a swirl pattern that created the lines. I took an

original piece to the local machinist, who spends most of his time

making industrial winches for fishing boats, and the thought of

making tiny swirls on aluminum was a challenge he was willing to

undertake.

Several that saw them deemed samples of his swirls on aluminum correct, and

so the technical challenge of recreating correct swirls on .032”

aluminum became the next challenge. The machinist does not have the

equipment to fold and stud the pieces that were originally folded and

studded, but we agreed that the thickness was correct, and that

formerly studded and fastened pieces could now be glued on.

by Doug Mayer

in that appliqué. I thought it looked pretty nifty. It was

only after I’d finished slathering that research suggested that

the real pattern was different.

in that appliqué. I thought it looked pretty nifty. It was

only after I’d finished slathering that research suggested that

the real pattern was different.

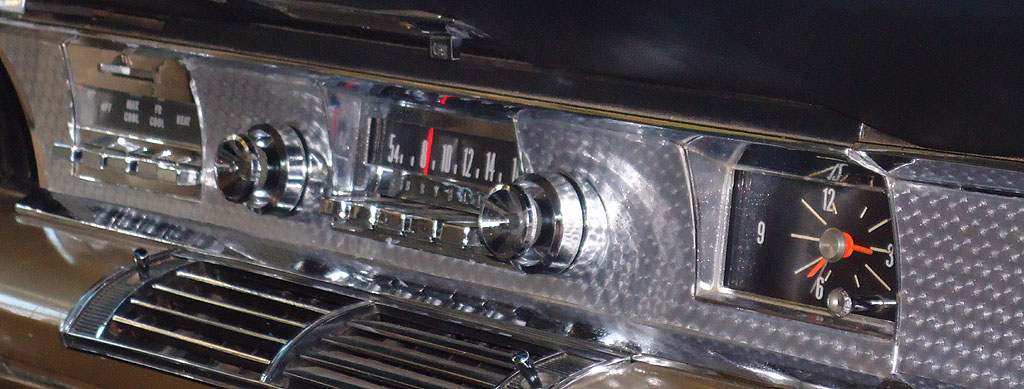

As you can see the centerpiece as seen

from the rear is folded over along the bottom and top, and there are

four studs along the bottom and three along the top (which I simply

drilled out.)

The right hand piece and the centerpiece were both attached with studs

welded to the aluminum and then a pal nut. The only way to get to

some of those studs/nuts is to remove the entire dash assembly, and I

chose not to do that.

The right side popped off with a narrow but wide bladed screwdriver; I

took what nuts I could off the centerpiece, but then drilled from the

front side to release the studs on the top and by the instrument

cluster bottom. The studs that I drilled out were attached to nuts

that were inaccessible without removing the whole shooting match.

The new pieces that I used have no folds, except for the arch at the top

of the glove box piece. I was worried about how these pieces would

look in place, but I am satisfied that they look as before they were

removed.

The right hand piece, to the right of the glove box is held in place by

JB Weld, and is likely there for the duration. The glove box is held

by the bezel at its bottom, and the hook over the top. The

centerpiece did not want to hold with a batch of JB Weld, which I

probably made incorrectly, so I used silicone. Of course the radio

knobs also hold it in place. The left hand piece is held in place by

the light and wiper switches, and is a bear to put on, since there

are few threads available for the wiper knob. A four-prong radio

antenna wrench is advised for the installation of the center and left

hand pieces; it makes getting the nuts threaded very much easier.

The whole dash has a curve, top to bottom, and the machine shop will bend

the pieces to approximately correct; I had some re-bending to do to

get them to fit a bit better. The material we used is a harder

aluminum, with more manganese than the original. It should hold the

pattern better than the original. I clear coated each piece a quick

coat or two, and would recommend doing that.

The result:

If you are interested in purchasing these replica dash pieces,

contact Doug Mayer at mobydoug@myfairpoint.net

Back